Last week we talked about March in Burton and the accompanying pancakes. This week I thought I’d talk a little bit about the process of making maple syrup itself. As I assume you all know, real maple syrup comes only from maple trees. We’re not talking the grocery store variety here. When I was growing up Mom bought us “Pancake Syrup” from the store, and I bet that it hadn’t even seen a picture of a maple tree. Not that we didn’t have real maple syrup in the house. My mom only served the real stuff to adults, as she said that it was just wasted on kid’s undiscriminating palates. As I got older though I tasted the real thing and now that’s all we keep in the house.

So, how does real maple syrup get out of the trees and onto your plate? The trees don’t just deliver it to the grocery store, you have to go out into the woods to hunt it where it lives. First you have to have a grove of Sugar Maple trees (a sugarbush to you city folks). Then in the early Spring you go out and”tap” the trees. This entails drilling a hole in the tree and pounding a “spile” into the hole. The spile is hollow and in the Spring the maple trees are busy bringing their sap, sweet with the fruits of last summer’s sunny growing season, up from their roots, where it has been stored all winter, to the branches where it will be used to help the trees bud out when the warm weather finally comes. This sap “run” will continue as long as the weather is warm during the day, and below freezing at night. Too warm or too cold and the run stops, and when the trees start to bud out, the sap changes flavor and the season is over for the year. So depending on the weather, you might get a long run, several short runs, or almost nothing at all. No wonder all the syrup producers are running around like a bunch of nervous hens this time of year.

Once the tree produces the sap it has to be transported to the sugar house for boiling. Easy, unless you count the heavy snow or deep mud common in the woods this time of year. Horse or tractor drawn sledges or wagons with a large gathering tank are the ticket for that. The new-fangled way to do it is to use tubing strung between the trees and run to a vacuum pump to suck the sap out of the woods. It requires less labor at gathering time than the traditional method, but there is also more off-season upkeep required to keep the tubing in good condition after the depredations of falling tree limbs and hungry squirrels.

Once in the sugar house, the real process of transforming the just slightly sweet sap to the thick syrup begins. Depending on the year, an average of 50 gallons of sap must be boiled down to yield just 1 gallon of syrup. That’s a lot of boiling. There is a new technology available to help that also, reverse osmosis. A reverse osmosis or “RO” system basically squeezes about half of the water out of the sap to concentrate it before it goes to the pan for boiling. A hydrometer that measures specific gravity tells the maple men when the syrup is done, and then its into the bottles and cans for packaging. Other end uses are maple candy and maple cream.

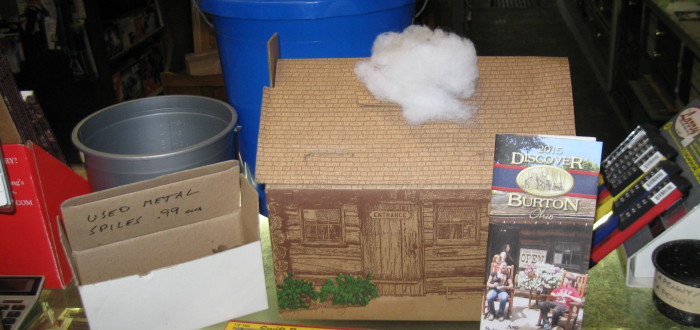

It is a fascinating process to watch, so if you see steam rising from the Burton Chamber of Commerce’s log cabin while driving around the square, stop in to check it out, and be sure to get yourself (and the kids) some of that that real all-natural maple goodness. It’s Mother Nature’s treat.